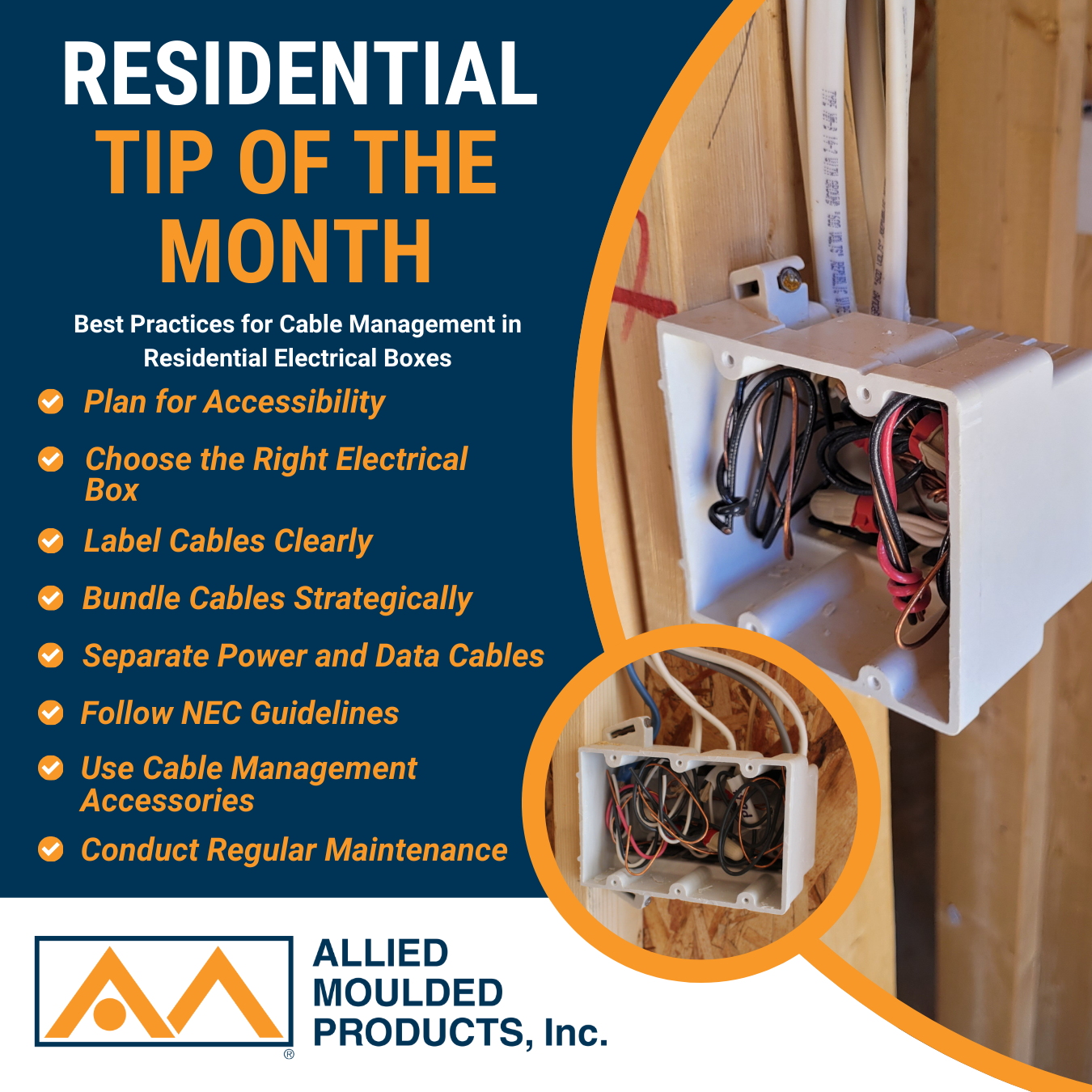

Best Practices for Cable Management in Residential Electrical Boxes

In the residential sector, effective cable management is more than a matter of aesthetics; it is critical for safety, efficiency, and compliance with stringent electrical codes. Properly managed cables minimize downtime, enhance system performance, and ensure that operations meet industry standards such as the National Electrical Code (NEC). This blog explores best practices for managing cables within industrial electrical boxes, helping professionals optimize their systems.

1. Plan for Accessibility

Before any cables are laid, prioritize accessibility for maintenance and troubleshooting.

- Tip: Use wiring diagrams to organize routes and anticipate future changes.

- Why it matters: Accessible cables reduce downtime during repairs and modifications.

2. Choose the Right Enclosure

Selecting an appropriate electrical enclosure is a foundational step in effective cable management.

- Material matters: Allied Moulded’s non-metallic enclosures, for instance, are corrosion-resistant and durable, ideal for harsh environments.

- Size up: Ensure the enclosure can accommodate all cables with room for growth.

3. Label Cables Clearly

Labeling cables helps distinguish their purpose, origin, and destination.

- Best tools: Use heat-shrink labels or pre-printed markers for durability.

- Bonus tip: Pair labels with corresponding documentation for quick reference.

4. Bundle Cables Strategically

Avoid chaotic cable sprawl by using bundling techniques.

- Options include:

- Cable tiesm for a firm hold, ensuring they are made of materials like nylon for industrial durability.

- Velcro straps for adjustable bundling needs.

- Safety note: Don’t over-tighten bundles, as this can damage insulation and lead to overheating.

5. Separate Power and Data Cables

Interference between power and data lines can degrade performance or cause malfunctions.

- Best practice: Maintain a minimum distance of 12 inches between high-voltage and low-voltage cables.

- Additions: Use barriers or separate conduits within the enclosure for better organization.

6. Follow NEC Guidelines

Compliance with the National Electrical Code ensures safety and legal adherence.

- Key requirements:

- Secure cables at specified intervals to prevent sagging.

- Use approved conduit fittings to protect wires entering or exiting the enclosure.

- Avoid overfilling conduit space to prevent overheating and stress.

- Benefit: Staying compliant protects workers and equipment while minimizing liability risks.

7.Use Cable Management Accessories

Accessories simplify and enhance cable organization.

- Examples include:

- Cable clamps to secure wires in place.

- Cable ducts to guide and protect cables.

- Grommets to safeguard against abrasion where cables pass through holes.

- Pro Tip: Choose accessories rated for industrial use to ensure longevity and reliability.

8. Conduct Regular Maintenance

Effective cable management requires ongoing attention.

- Checklist:

- Inspect for wear, fraying, or overheating.

- Confirm labels remain legible and intact.

- Adjust bundles or ties as needed to accommodate new cables.

- Outcome: A well-maintained system prevents costly downtime and ensures long-term safety.

The Allied Moulded Advantage

Allied Moulded Products offers a wide range of non-metallic electrical enclosures tailored to meet the demands of residential applications. Designed for durability, our enclosures support best practices in cable management, ensuring your systems are efficient, safe, and compliant.

Proper cable management is a cornerstone of safe and efficient industrial operations. By following these best practices, professionals can optimize system performance and uphold the highest standards of safety and compliance. Ready to streamline your cable management process? Explore Allied Moulded solutions today!