When working in residential construction, there are a lot of choices that go into each build. Whether you’re doing a single, custom home or an entire subdivision, every choice impacts the cost and quality of the home.

That all extends to electrical enclosures too. They’re an essential part of the project, and picking the right boxes can keep costs down and provide better options for wiring throughout the house. So, what do you need? Which material is the right choice for residential projects?

In general, you have three options: polycarbonate, fiberglass, and metal. When you know more about each option, you can make the right choice for your project.

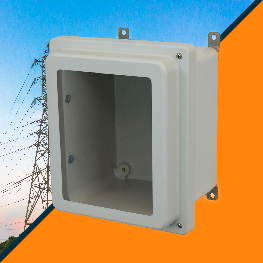

Polycarbonate

Polycarbonate is the most common material for indoor electrical boxes for a few reasons. First, it’s very affordable. You will pay less per box than with pretty much any other material. On top of that, it provides everything you need for indoor use. Polycarbonate is a good electrical insulator. It’s easy to modify when you need to customize the box.

Polycarbonate is also aesthetic for any applications that might leave the box exposed. Using it won’t leave eyesores.

Perhaps the greatest advantage of polycarbonate is that you will find models already designed for all common residential uses, including junction boxes, outlets, switches, fan boxes, and more.

Fiberglass

The truth is that fiberglass is very competitive with polycarbonate. Everything poly does, fiberglass does too. Fiberglass is a great insulator and easily modified. It’s tough. It does great indoors, and it’s affordable.

There are two reasons why you see more polycarbonate for residential applications. The first is that fiberglass is extremely resilient in the face of harsh chemicals, like powerful solvents. That’s not important in residential applications.

The second issue is that fiberglass typically costs more per unit than polycarbonate. Fiberglass is affordable, but since it provides benefits that aren’t very useful in residential applications, most developers opt for the even more affordable option.

Metal

For residential use, there are really only two times to use a metal enclosure. The first is for wiring metal-sheathed conduit. In such a case, it is a requirement to use metal, as it offers additional grounding.

For new builds, that’s an uncommon need, which means that the vast majority of times you will see metal boxes is for outdoor use. Especially if there is an outdoor circuit breaker, metal is the weatherproof option that does well.

Most of the time, outdoor boxes will be made from aluminum, but there are times when you might see galvanized steel. Typically, aluminum is the better choice as it is much more resilient against weather and rust.

Great Boxes at Allied Moulded

Regardless of the material you choose, you can get great electrical enclosures from Allied Moulded. We have a wide selection of already fabricated boxes. We also offer customization services. If you’re working on a project that requires specialized boxes for any reason, we will partner with you to design an affordable, scalable option that gets the job done.

Contact us today. We’ll walk you through the selection and help you find the perfect boxes for your project.