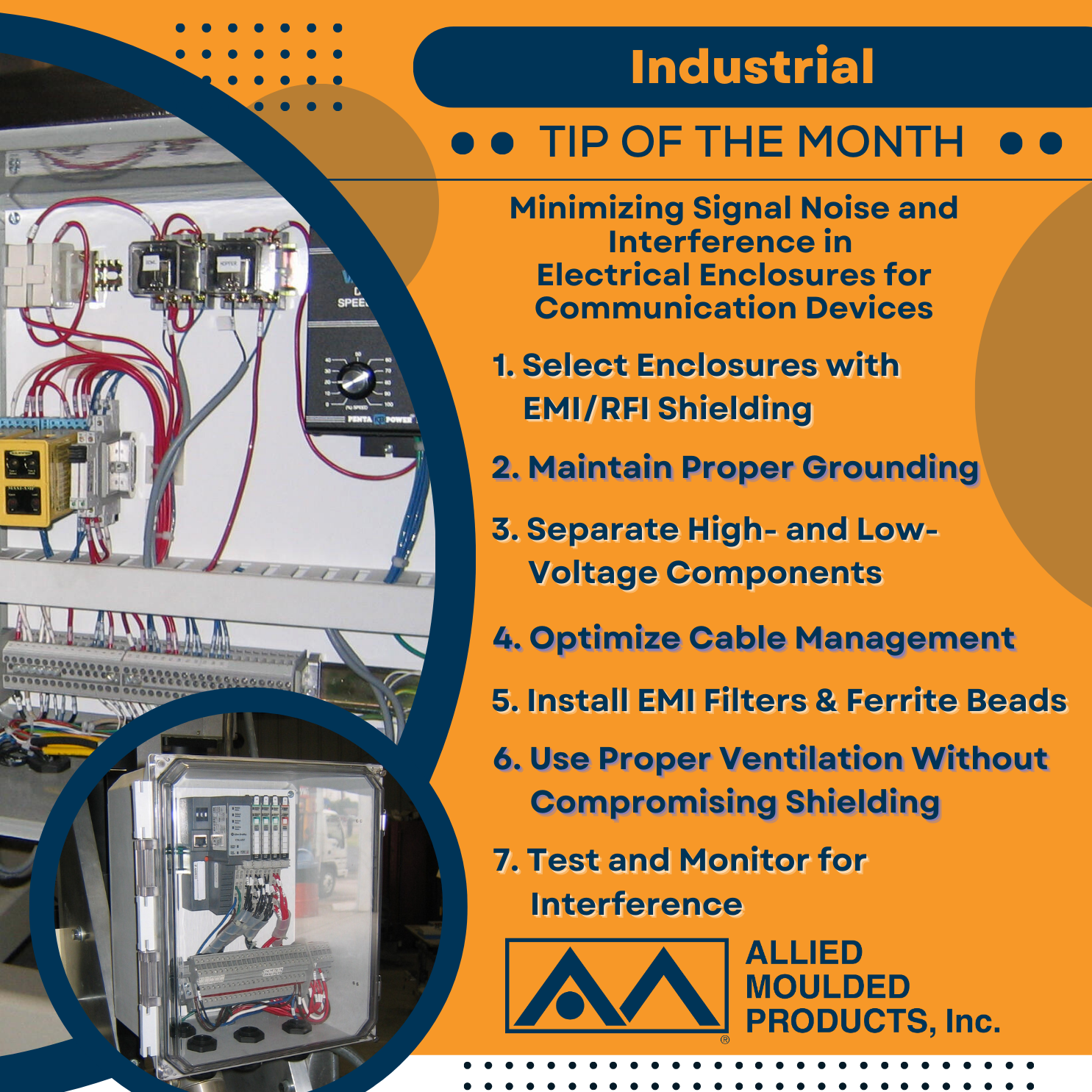

In industrial environments, electrical enclosures protect critical communication devices from physical damage, moisture, and contaminants. However, these enclosures must also address an often-overlooked challenge: signal noise and interference. Left unchecked, electromagnetic interference (EMI) can disrupt device performance, leading to communication errors, reduced efficiency, or downtime. Here are key methods to minimize signal noise and interference in electrical enclosures and maintain seamless operations.

Understanding Signal Noise and Interference

Signal noise refers to unwanted electrical signals that can distort or block communication between devices. Interference can arise from internal components, external equipment, or even the environment itself. The primary culprits include:

- Electromagnetic Interference (EMI): Generated by motors, transformers, and other equipment.

- Radio Frequency Interference (RFI): Resulting from wireless communication devices and high-frequency signals.

Methods to Minimize Signal Noise and Interference

1. Select Enclosures with EMI/RFI Shielding

The first line of defense against signal noise is an enclosure designed to block interference. Look for enclosures with built-in shielding capabilities, such as:

- Metallic Enclosures: Materials like steel or aluminum naturally block EMI and RFI, making them an excellent choice for high-interference areas.

- Coated Non-Metallic Enclosures: Non-metallic enclosures with conductive coatings or linings combine lightweight durability with shielding capabilities, offering a versatile solution. Allied Moulded offers a range of non-metallic enclosures that can be customized with shielding options to meet specific industrial needs.

2. Maintain Proper Grounding

Grounding is critical for reducing signal noise. Ensure that all enclosure components, including cables and equipment, are properly grounded to create a clear path for unwanted signals to dissipate. Key practices include:

- Using ground bars or plates inside the enclosure for secure connections.

- Verifying continuity between the enclosure, mounting hardware, and grounding system.

3. Separate High- and Low-Voltage Components

High-voltage equipment can create significant EMI that affects low-voltage communication devices. To minimize this risk:

- Physically separate high- and low-voltage systems within the enclosure.

- Use divider panels or barriers to isolate different types of components.

- Route power and communication cables on opposite sides of the enclosure.

4. Optimize Cable Management

Poor cable organization is a common source of interference. Implement these cable management strategies:

- Twisted Pair Cabling: Twisting pairs of wires reduces susceptibility to electromagnetic interference.

- Shielded Cables: Use cables with conductive shielding to block external noise.

- Cable Routing: Avoid running communication cables parallel to power lines, as this can amplify interference. Instead, cross them at right angles when necessary.

5. Install EMI Filters and Ferrite Beads

Active noise reduction components can significantly improve signal integrity:

- EMI Filters: Install filters on power lines entering the enclosure to suppress noise at the source.

- Ferrite Beads: Attach these to cables to block high-frequency interference.

6. Use Proper Ventilation Without Compromising Shielding

While ventilation prevents overheating, open vents can introduce interference. Use EMI-shielded ventilation panels to maintain airflow while blocking unwanted signals.

7. Test and Monitor for Interference

Regular testing ensures your enclosure remains interference-free:

- Use spectrum analyzers or EMI detectors to identify problem areas.

- Conduct tests during installation and periodically as part of routine maintenance.

Why It Matters

Minimizing signal noise and interference in electrical enclosures ensures that your communication devices operate efficiently and reliably. This is particularly critical in industrial settings where consistent performance can directly impact safety and productivity.

Allied Moulded’s non-metallic enclosures are designed to protect sensitive equipment while providing options for shielding and customization. Durable, lightweight, and versatile, these enclosures are the ideal choice for addressing interference challenges in demanding industrial environments.

Explore Allied Moulded’s electrical enclosures and discover how our solutions can enhance your operations.